45V Hydrogen Tax Credit Rules Delayed: Three Things Project Developers Need to Know Ahead of Anticipated Treasury Department Guidance

Find out what steps project developers can take now amid the Treasury Department’s anticipated delay in issuing guidance on the 45V hydrogen tax credit.

By Tanya Peacock, Managing Director, California and Hydrogen

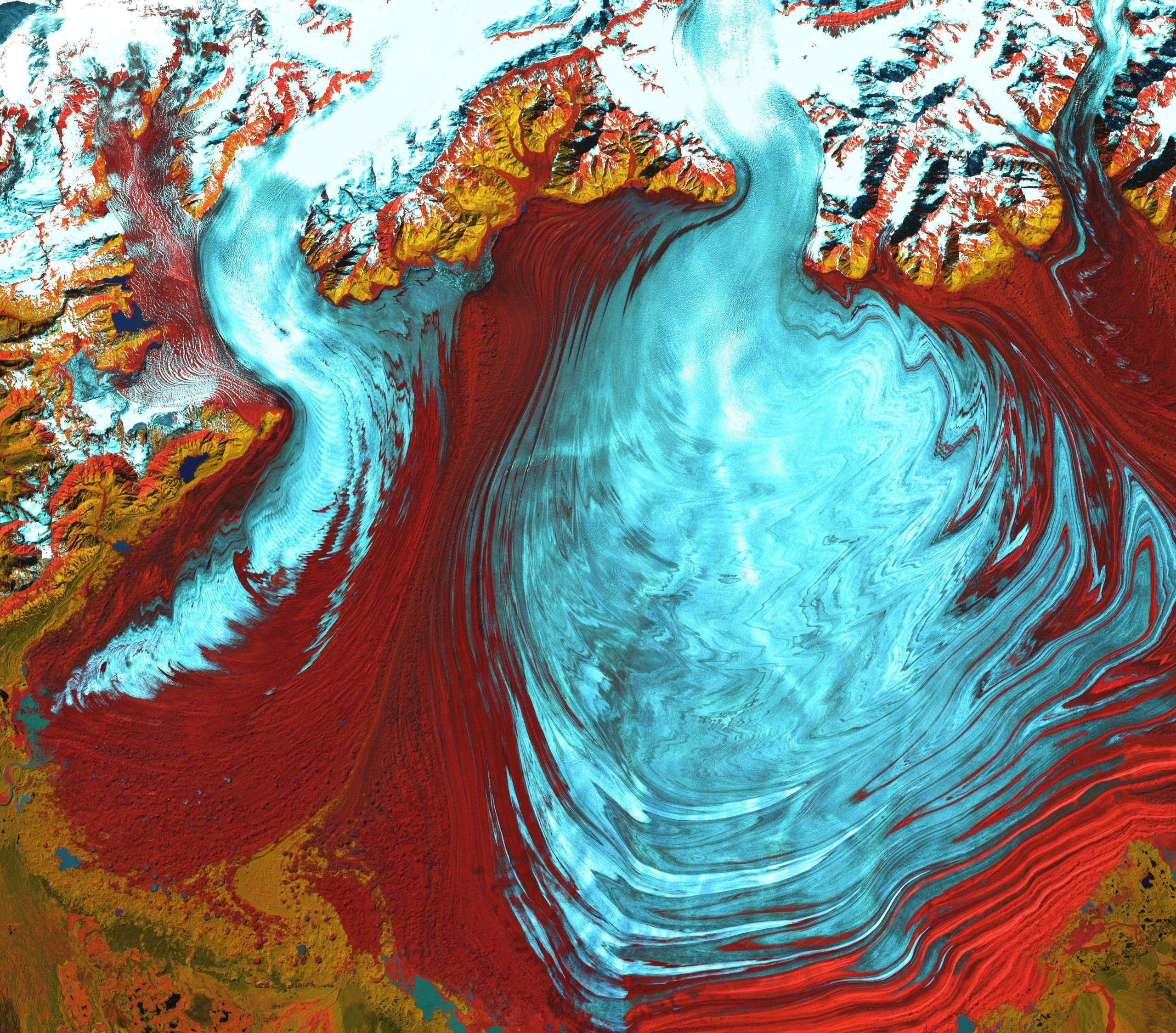

Clean hydrogen is key to reducing emissions, particularly from hard-to-abate sectors like the steel, cement, fertilizer, and chemicals industries, as well as transportation. Signed into law last year, the Inflation Reduction Act (IRA) includes potentially more than $100 billion of tax incentives over its lifetime for project developers to seize on and set in motion the nascent clean hydrogen economy on a path for rapid growth.

The IRA requires emissions from hydrogen production to be less than 0.45 kg CO2e/kg to qualify for the full ($3.0/kg) 45V clean hydrogen production tax credit and must be 4 kg CO2e/kg or lower on a well-to-gate life-cycle basis to quality for partial credit. This 10-year tax credit is extremely valuable and represents a substantial share of the economic proposition for clean hydrogen production.

READ MORE: Clean Hydrogen Fuel Has Important Potential for Decarbonization Goals

The IRA requires the U.S. Treasury Department to publish guidance for calculating the lifecycle greenhouse gas (GHG) emissions of hydrogen projects within one year of its enactment. Because the law was signed on August 16, 2022, that deadline is unlikely to be met. According to media reports, Treasury Department guidance for the 45V hydrogen tax credit is not expected to come out until October and may be as late as December, potentially missing the deadline by as much as four months.

What Can Hydrogen Project Developers Do Now?

So, what can project developers do now to keep their hydrogen projects on track amid the anticipated delayed guidance from the Treasury Department on the 45V hydrogen tax credit? Below are recommendations on what hydrogen project developers can do now to be prepared and how EcoEngineers can help you gain full benefit and monetization of the 45V hydrogen tax credit.

-

Know the Base Case Carbon Intensity (CI) Score of Your Planned Project

A CI score is the aggregated GHG emissions during the life cycle of a fuel divided by the quantity of the fuel. To qualify for the 45V hydrogen tax credit under the IRA, developers will need a Life-Cycle Assessment (LCA) to determine if the hydrogen has a CI score of 4 kg CO2e/kg of hydrogen or lower on a well-to-gate basis. An LCA should be conducted by experts as early as possible in the project development cycle using the correct model(s) with the correct inputs. Sensitivity analyses can be run based on various 45V scenarios to help manage risk and guide investment decisions. If your actual CI is higher than originally expected, millions of dollars could be lost. -

Understand All Regulatory and Permitting Requirements (And Value Streams)

While waiting for 45V guidance, project developers should consult with appropriate experts for a thorough review of all regulatory and permitting application and compliance requirements. Understanding and potentially lining up required approvals, inspections, and reviews will help ensure the product can be sold to the intended parties and facilitates claiming essential credits. Additionally, a regulatory plan can include an evaluation of credits and incentives available for the project. -

Conduct a Due Diligence Study on Selected Technology

Take the time to review the process performance demonstration run data provided by your technology vendor. Are the claims of the product quality, process operability (days on stream/year), emissions levels, and operating costs accurate? Having a third-party expert review your process performance guarantee now could save you millions of dollars in the future.

EcoEngineers has performed more than 500 LCAs since 2015. We have experience in all the regulations that require LCAs, including the U.S. Renewable Fuel Standard (RFS), California Low-Carbon Fuel Standard (LCFS), Oregon Clean Fuels Program (CFP), Canada Clean Fuel Regulations (CFR), British Columbia Renewable and Low-Carbon Fuel Requirements (RLCFR), Brazil RenovaBio, EU Renewable Energy Directive (RED) and impending directives, along with emerging Voluntary Carbon Markets.

READ MORE: Life-Cycle Analysis and Clean Hydrogen Consulting

With more than 200 asset development engagements and $4 billion of investments for projects across decarbonization projects and technologies, Eco’s team of experts can provide individualized guidance throughout the entire project development lifecycle of your hydrogen project. From design, build, and operational phases to regulatory and permitting guidance, technology and market risk assessments, startup optimization, and capital raising evaluations – we have you covered.

For more information about our clean hydrogen services, contact:

Tanya Peacock, Managing Director, California and Hydrogen | tpeacock@ecoengineers.us